DWR Super Finishing Stone

Super Finishing Stone is used for the final finishing product to make a very high quality product. Stone are generally produced tailored (shape, size) according to customer requirements.

Artificial abrasive material #1000 to #8000 is used for product for Bearing.

The abrasive grains is used by the state of the Japanese company F. F's grains are excellent and reliable products that Dawoori as well as several leading companies use. (import WA, GC, CA, A)

The following products are used with the Super Finishing Stone.

- Super Finishing Stone is used to finish Taper Bearing, Taper Roller Bearing, Ball Bearing. (IR & OR)

- Finishing of the hydraulic cylinder and piston

- Mold Making

- Mold making is used in a number of products according to the bearing shaft of the rotary compressor and the pump and other needs.

Dawoori Succeeded development of Super Finishing Stone in 2002 and supplies it to the leading bearing company. Keep working on the sustainable development and let customer suggest the best product for the products quality specifications and the customized products if needed.

Try to complete the Super Finishing Stone for better performance through stringent verification by the Stone Test Machine.

Dawoori's Super Finishing Stone

- High workability

- Long life

- Good quality

- Cost reduction

We will be the best partner, doing the best to produce better quality products to meet the customer's need

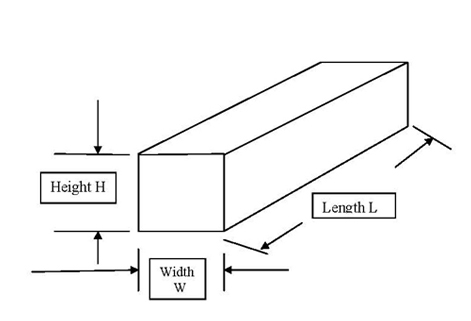

Super Finishing Stone's Drawing

Specifications Of Super Finishing Stone

Taper bearing

Taper Roller bearing

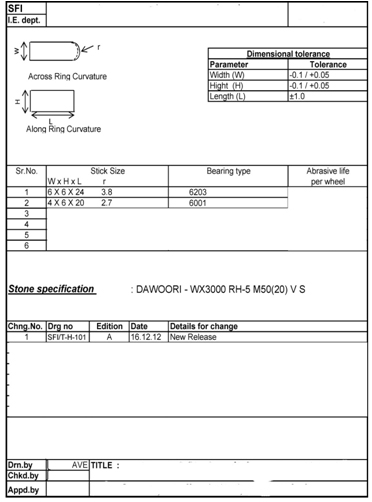

The first bond of Dawoori

The second bond of Dawoori

Picture of the third bond of Dawoori

The bond acts as a skeleton which binds the abrasive grain, pore and different types of grinding wheel materials.Characteristics of the product of 1,2 and 3 bonds can be changed in accordance with the ratio.

Therefore, we strictly control in accordance with the self-regulation of the production control of bond

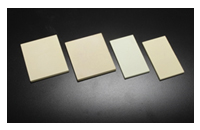

Picture of pore system

The roles of pore system are heat generation in the grinding process by securing a space between the abrasive grain and bond and preventing development of eyes dream of wheel and creating the surface of good quality.

Dawoori imports pore system from Japanese Company S.

Ball bearing